Exhibition direct hit | Moji Nano Technology invites you to witness the new wave of cutting-edge photoelectric technology

Release Time:

2025-03-12

On March 11, 2025, the 20th Munich Shanghai Optical Fair (LASER CHINA 2025) opened in honor at the Shanghai New International Expo Center.As Asia's most high-specification photoelectric technology exhibition, this year's event brought together more than a thousand leading companies from dozens of countries and regions around the world to share a feast of photoelectric technology.Moji Nano Technology brought key technologies and equipment to booth N2-2436!

On March 11, 2025, the 20th Munich Shanghai Optical Fair (LASER CHINA 2025) opened in honor at the Shanghai New International Expo Center.As Asia's most high-specification photoelectric technology exhibition, this year's event brought together more than a thousand leading companies from dozens of countries and regions around the world to share a feast of photoelectric technology.Moji Nano Technology brought key technologies and equipment to booth N2-2436!

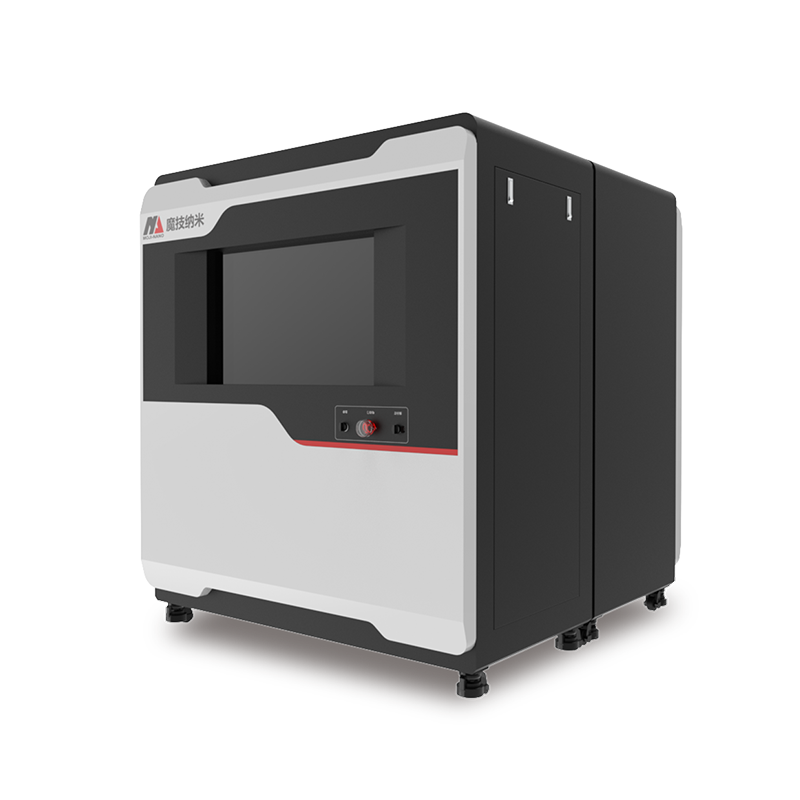

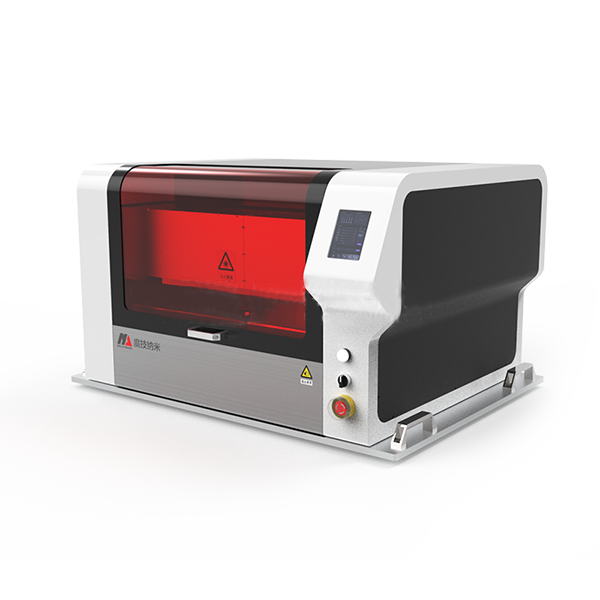

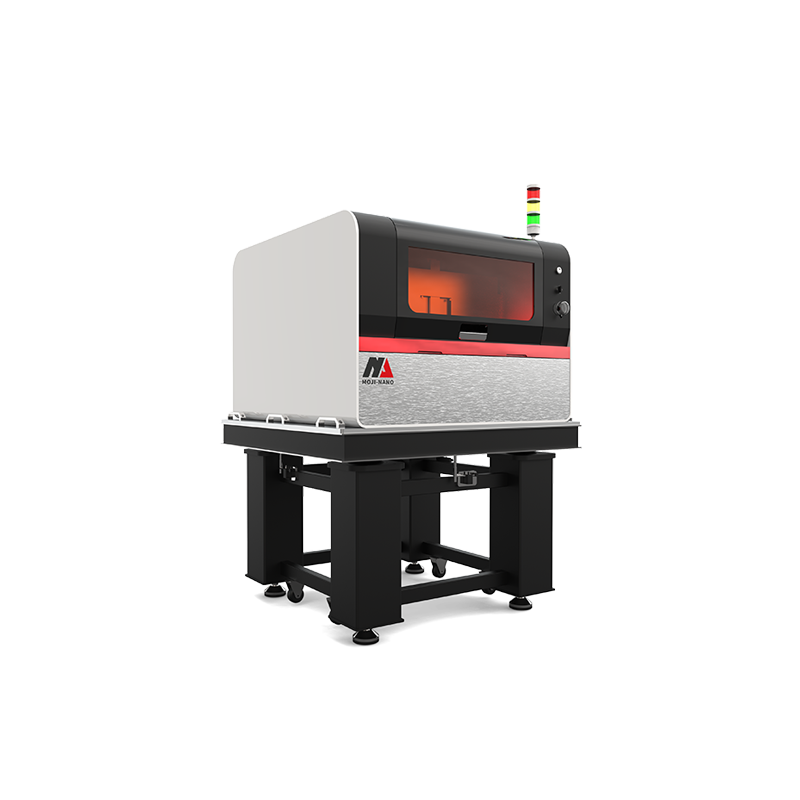

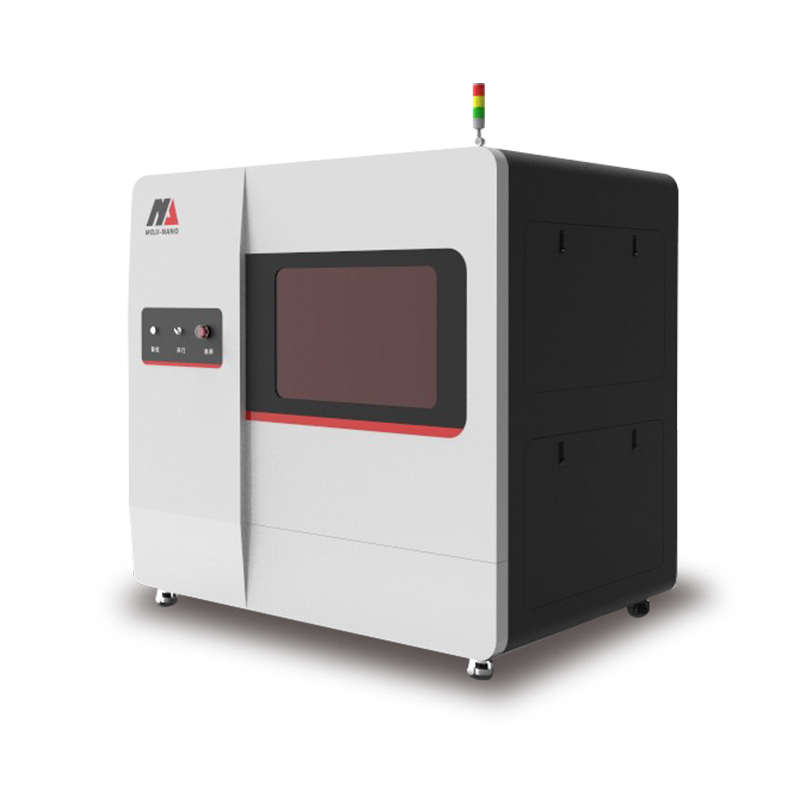

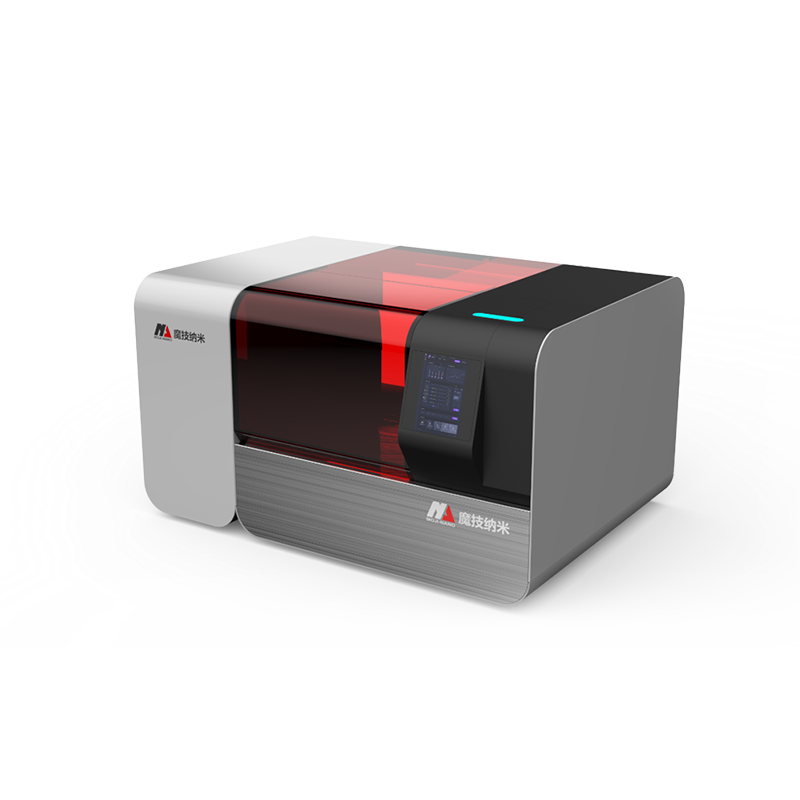

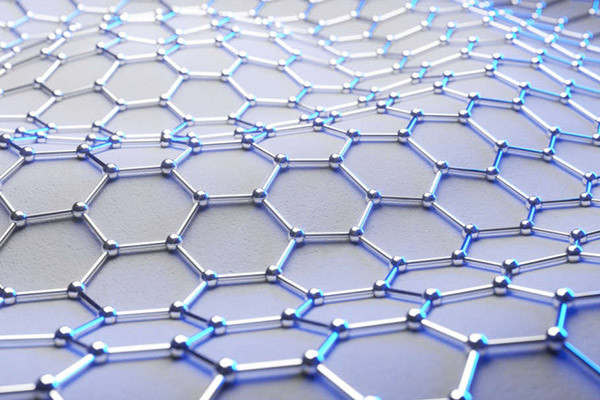

Moji Nano Technology is committed to providing customers with high-quality high-end equipment and overall solutions in the field of three-dimensional micro-nano manufacturing. The independent research and development and production of three-dimensional micro-nano processing/nano 3D printing equipment, ultra-fast laser micro-nano processing centers and mask-free direct writing lithography equipment will redefine the industrial boundaries of three-dimensional micro-nano manufacturing and build a multi-dimensional, wide-writing field, and cross-scale nano-scale integrated manufacturing system!

Panoramic display of technology empowerment in high-precision fields

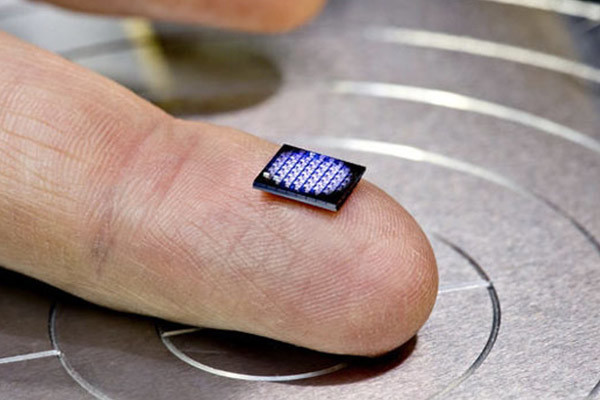

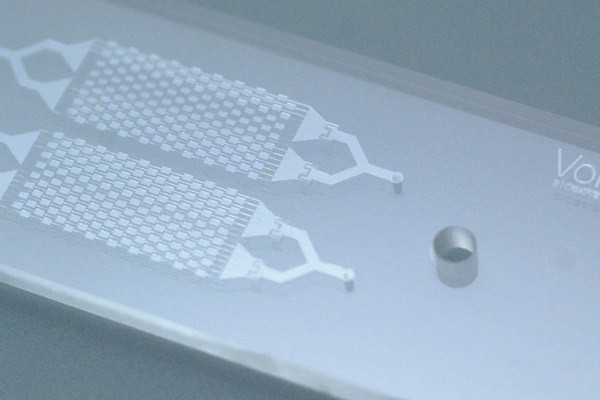

At this exhibition, Moji Nano Technology publicly demonstrated examples of nano-scale three-dimensional processing in the following strategic fields, covering high-precision multi-function device structure processing in the fields of electronic information, biomedicine, optical communications, and new materials.

Visualization of microstructure detonated the audience craze

The immersive experience area of the booth was crowded with people. The colleagues who watched the exhibition “saw” the internal structure of nano-scale three-dimensional printing through a microscope, as if entering the microscopic world, and intuitively felt the shocking power of technological breakthroughs.Moji Nano Technology strengthens technical memory points by enhancing the sense of participation, and has become the focus of the audience's “phenomenon-level” popularity!

Moji Nano Technology sincerely invites colleagues from the industry to visit booth N2-2436 to jointly decode the new industrial paradigm of three dimensions of three-dimensional micro-nano processing/nano 3D printing, ultra-fast laser micro-nano processing, and mask-free direct writing lithography!

Let us reshape the cognitive boundaries of traditional manufacturing in the wave of the new qualitative productivity revolution of three-dimensional micro-nano manufacturing, jointly paint the sea of stars of intelligent manufacturing, and jointly create the future of intelligent technology!

About Moji Nano Technology

Moji Technology Nano technology is a high-tech enterprise integrating R&D, production, sales and service in the field of three-dimensional micro-nano manufacturing, and a provincial specialized and special new enterprise.The R&D team has more than ten years of experience in micro-nano three-dimensional manufacturing technology, has complete independent development capabilities, and can provide professional integrated solutions for multi-industry application scenarios.

The company has launched three series of three-dimensional micro-nano processing/nano-3D printing equipment, ultra-fast laser micro-nano processing centers, mask-free direct writing lithography equipment and a variety of photoresist products. Among them, the independently developed commercial nano-scale three-dimensional laser direct writing lithography system can achieve three-dimensional structure processing with an accuracy of 70 nm.Relying on the advantages of core technologies such as high precision, high speed, large format and long-term stability, it has achieved a leap from scientific research exploration to commercial application, and has effectively promoted the large-scale industrial production of micro-nano three-dimensional manufacturing in biomedical, photoelectric communications, new materials, micro-nano devices, aerospace and other fields.

News Recommendation