Bid Farewell to "Snail-Paced" Manufacturing: NanoBoostPrinter Kicks Off an Efficiency Revolution in Nano-3D Printing

Release Time:

2025-08-12

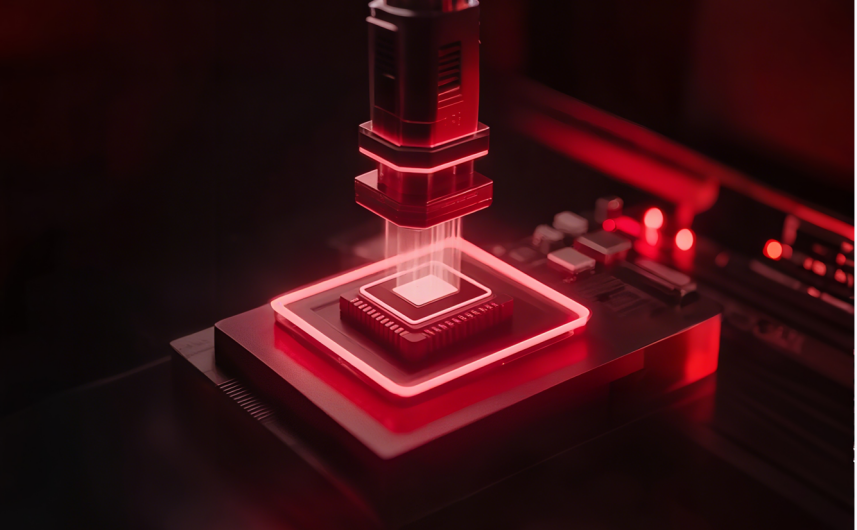

In the field of micro-nano manufacturing, Multiphoton Polymerization (MPP) technology is hailed as the key to unlocking the era of "free nano-manufacturing."

In the field of micro-nano manufacturing, Multiphoton Polymerization (MPP) technology is hailed as the key to unlocking the era of "free nano-manufacturing." It enables the construction of high-resolution structures with an extremely high degree of freedom in three-dimensional space, and is widely applied in cutting-edge fields such as micro-optics, microfluidics, biological scaffolds, and microrobots. However, until recently, efficiency has remained the biggest bottleneck restricting its industrial mass production and large-scale application.

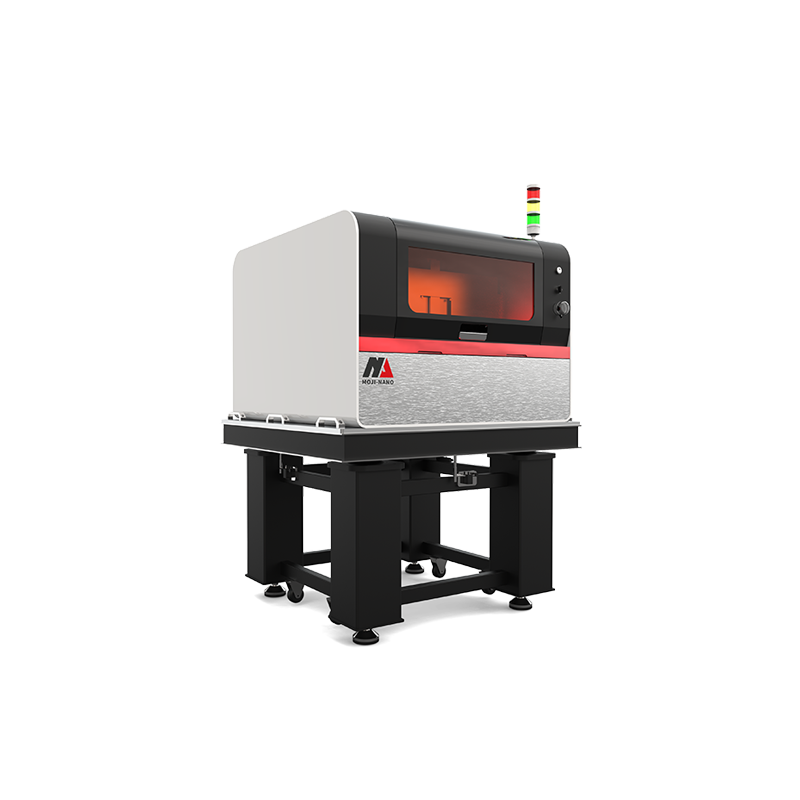

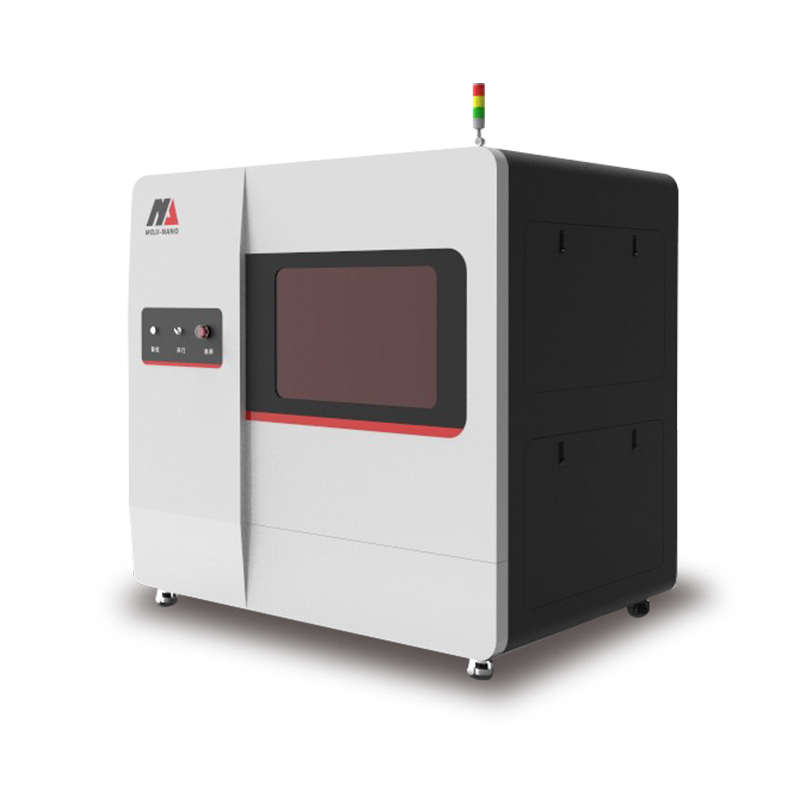

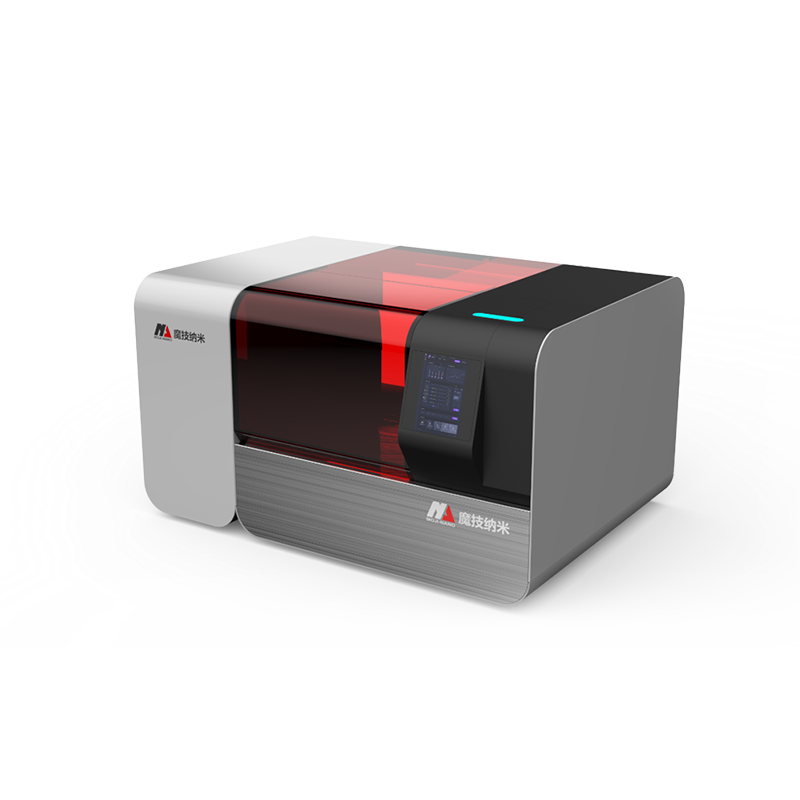

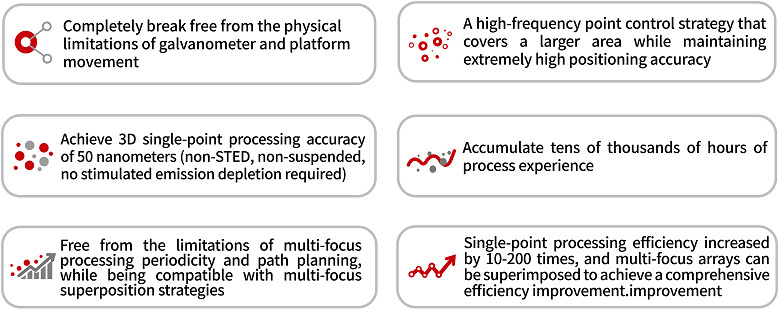

Today, we bring a revolutionary technological breakthrough – the NanoBoostPrinter technology platform. Since its establishment in 2018, moji nano has served over 300 customers and accumulated tens of thousands of hours of printing experience. Building on this foundation, we officially launched this epoch-making achievement in 2024. It completely breaks the "path-scanning" efficiency bottleneck in traditional multiphoton polymerization, elevating nano-printing from a "laboratory device" to an "industrial tool."

I. Multiphoton Polymerization: The Core Principle of Micro-Nano 3D Printing

Multiphoton polymerization is a high-precision 3D manufacturing technology that uses ultra-fast lasers (typically femtosecond lasers) to trigger nonlinear absorption reactions in photosensitive resins, achieving sub-wavelength precision curing.

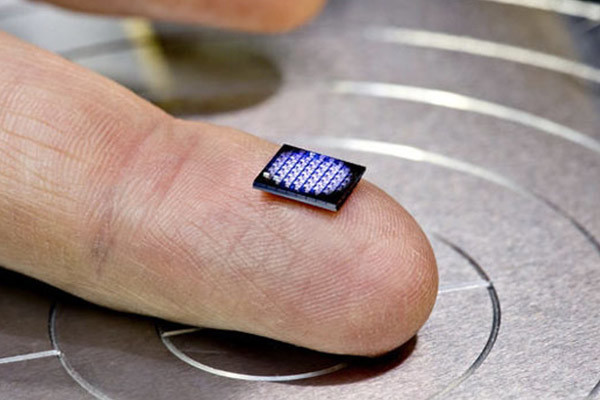

Traditional single-photon curing can only achieve exposure on the surface, while multiphoton polymerization relies on high-intensity lasers to induce polymerization reactions near the focal point, enabling "writing" of structures at any 3D coordinate position inside the material. Its spatial resolution can reach hundreds of nanometers or even lower, making it a true form of "volumetric pixel printing."

II. Limitations of Traditional Methods: The Dilemma of Galvanometer and Motion Stage Scanning

Currently, mainstream multiphoton printing equipment on the market generally adopts two path-scanning methods:

Galvanometer scanning system: Drives the lens to move the laser focus rapidly via current to achieve fast scanning;

Nano-scale motion stage: Moves the objective lens or sample via a high-precision stage to achieve large-size scanning.

Although these solutions have achieved relatively high precision, they are always limited by issues such as inertia, acceleration, and synchronization of scanning components. When processing complex large-volume structures or large-batch tasks, efficiency is severely constrained. Printing a structure of only millimeter scale often takes several hours or even longer, which greatly limits the expansion of application scenarios.

III. Outstanding Application Achievements, but Mass Production Roadblocked

Multiphoton polymerization technology has already demonstrated great potential in a number of cutting-edge fields:

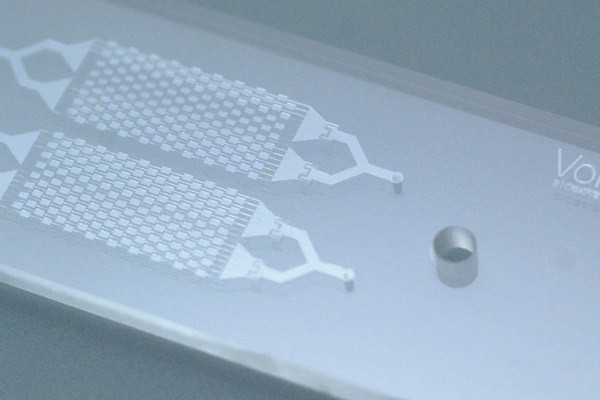

Micro-optical structures: Free-form surface lenses, micro-gratings, polarization control elements;

Silicon photonics technology: Co-packaged optics, heterogeneous material integration, etc.;

Microfluidic chips: Cell manipulation, micro-mixers, quantitative pumps and valves;

Biological scaffolds: Simulating extracellular matrix, directional growth channels;

Flexible microrobots: Sub-millimeter micro-grippers, swimming devices;

However, most of these cases remain in the stages of laboratory verification and small-batch sample production. The core crux lies in the mismatch between printing efficiency and the needs of practical applications.

IV. NanoBoostPrinter Technology: An Efficiency Revolution Breaking Traditional Constraints

Our independently developed NanoBoostPrinter platform adopts an entirely new efficient point selection and focusing method, breaking through the speed and precision limitations of traditional path-scanning methods and redefining the speed limit of nano-printing.

Core Advantage:

The improvement in single-point processing efficiency means that a structure that originally took 3 hours to print can now be completed in less than 1 minute. At the same time, when combined with the multi-focus expansion module, the mass production of high-complexity nano-structure printing will shift from "calculated by days" to "counted by seconds."

V. Multiple Transformations Driven by the Exponential Leap in Processing Efficiency

Improving efficiency is not just about "saving time"; it directly brings about the following changes:

From single-piece processing to mass manufacturing: Printing that used to take days is now done in hours, supporting high-throughput R&D and production;

No more compromises on structural complexity: Higher efficiency enables higher resolution and more complex structures;

Significant reduction in processing costs: Improved equipment utilization, with unit costs dropping by over 80%;

Wider application implementation: Can be deeply integrated into industrial scenarios such as consumer electronics, medical devices, and aerospace;

The upcoming NanoBoost Generation 2 platform is expected to further enhance efficiency and spatial control flexibility, truly realizing "industrial acceleration" and "industrial transformation" in nano-manufacturing.

VI. Conclusion: Usher in a New Era of "Both Efficiency and Precision"

The launch of NanoBoostPrinter technology is not only the result of moji nano’s years of accumulation and collaborative iteration with customers, achieving a leapfrog upgrade in equipment performance, but also a symbol that the entire nano-3D printing industry has entered a new phase of industrial acceleration.

In the crucial decade of "technology advancing toward industry," we aim to leverage this transformative efficiency improvement to drive multiphoton polymerization technology out of laboratories and into more practical application scenarios. We strive to make "nano-scale manufacturing" truly serve the high-end intelligent manufacturing and micro-level innovation of the future world, and accomplish the leap from industrialized production to an industrialized ecosystem.

Welcome to Cooperation and Communication

If you are interested in the NanoBoostPrinter technology platform, now is the best time to join this technological revolution! Please feel free to contact us to schedule tests, conduct technical docking, or carry out joint development. Let us work together to push micro-nano manufacturing into a new era of high efficiency and practical application!

News Recommendation