Nano Dimension shows new micro AM machines at Formnext 2023

Release Time:

2023-10-17

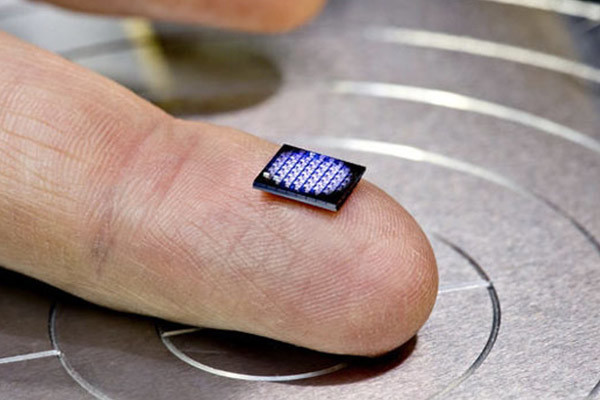

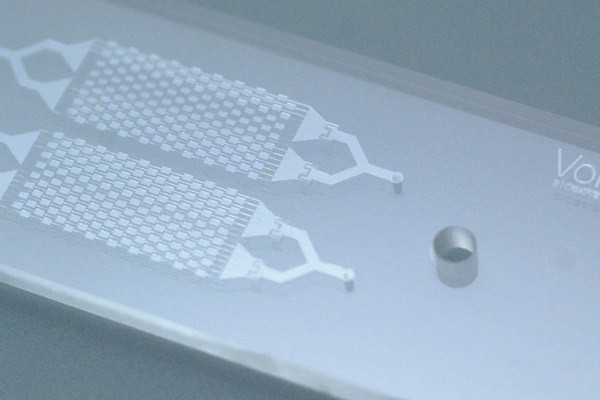

Nano Dimension’s Tera 250 Micro-AM solution has been providing the benefits of AM to the micro manufacturing community and helping companies develop innovative products with micron tolerances for some time.

Nano Dimension’s Tera 250 Micro-AM solution has been providing the benefits of AM to the micro manufacturing community and helping companies develop innovative products with micron tolerances for some time.

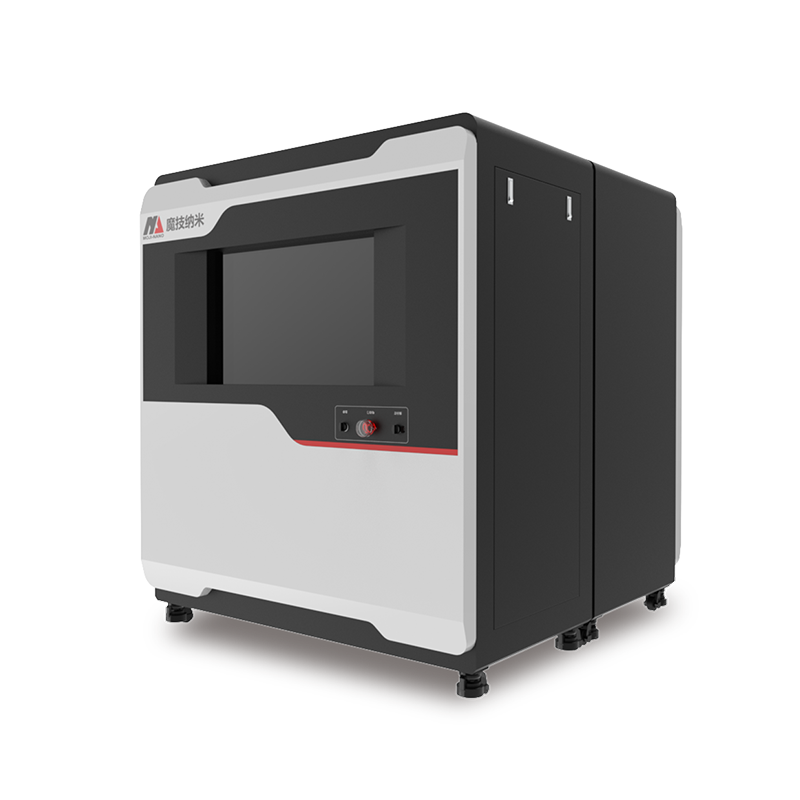

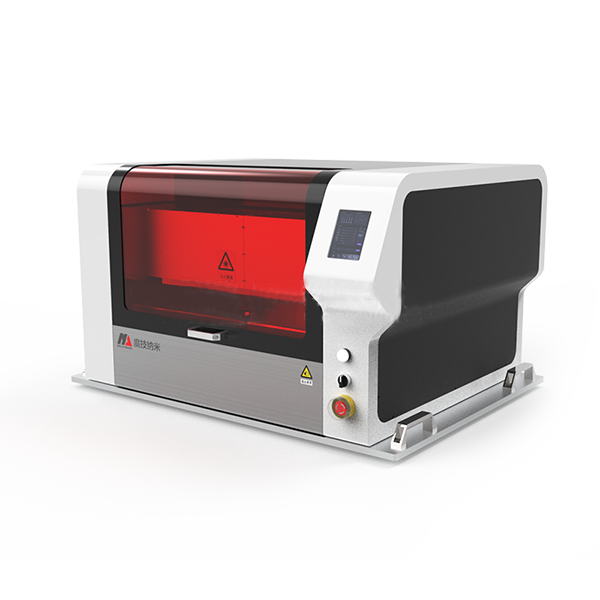

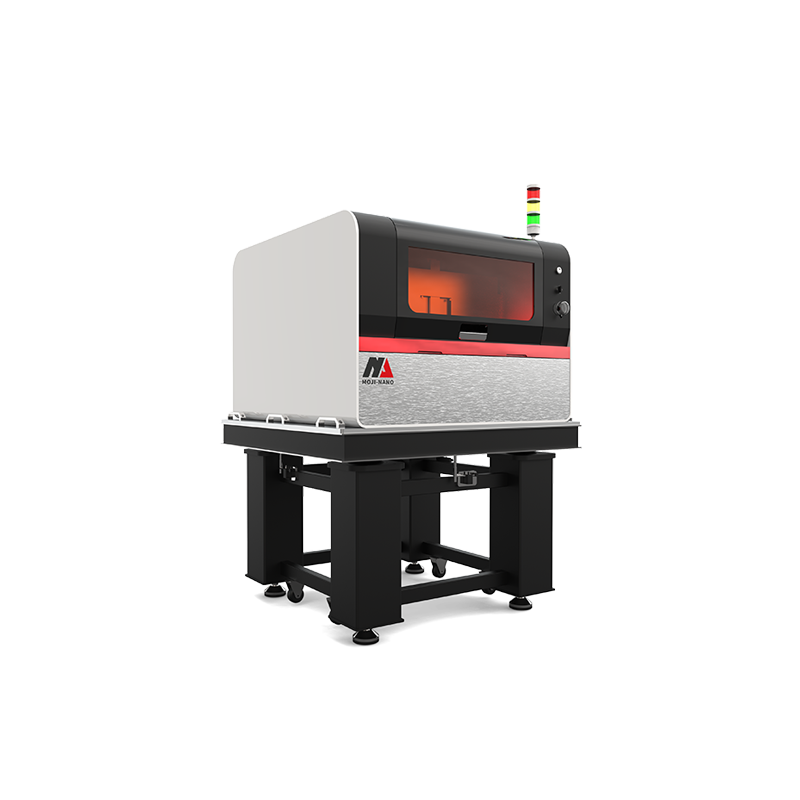

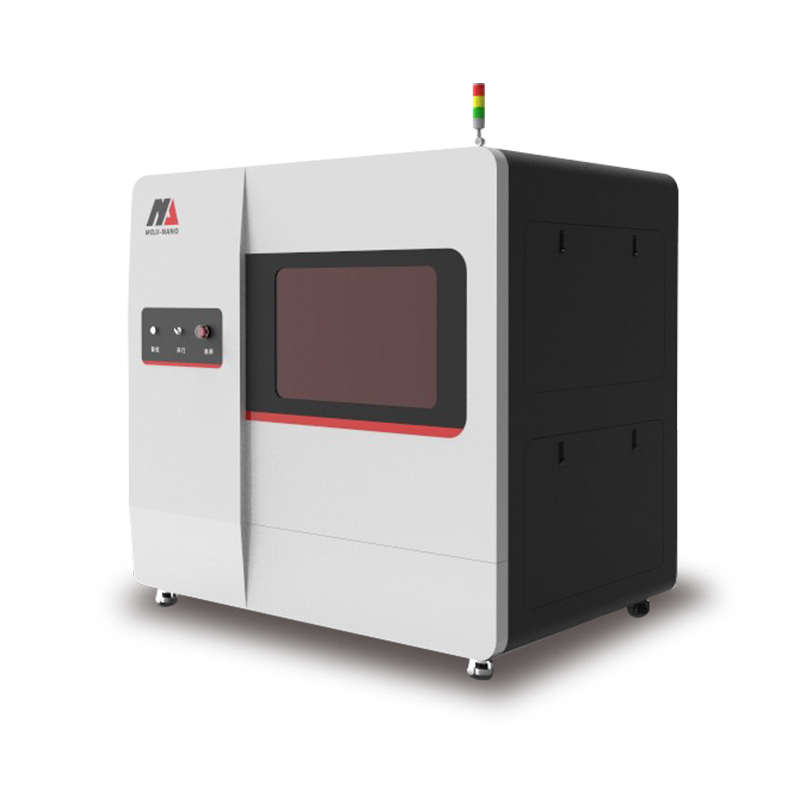

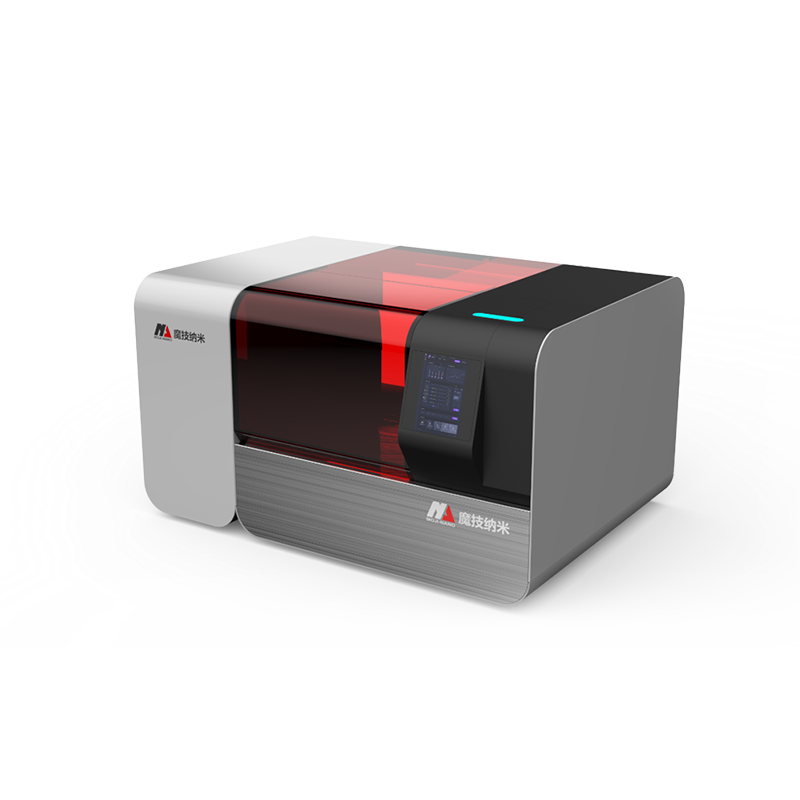

Building on this success, and in response to the burgeoning demand from companies demanding innovative, speedy, and cost-effective precision part development, the company has recently announced an expanded additive manufacturing product line with a new range of Fabrica Micro-AM solutions with several additional systems known as the Tera 25, the Giga 250, and the Giga 25.

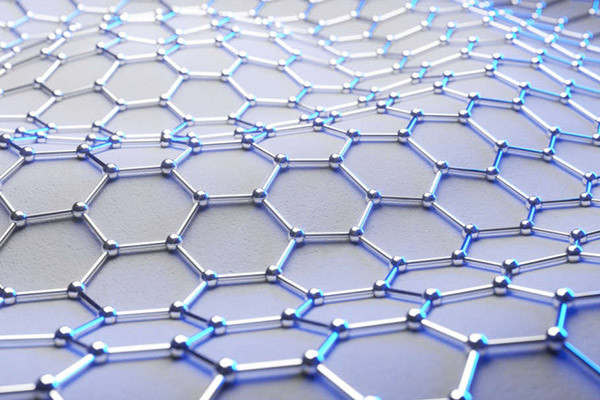

Nano Dimensions’ AM group expands the Fabrica Micro-AM product line. Image courtesy of Nano Dimension.

“Nano Dimension is responding to an exponential interest from industry, and our Fabrica range of Micro-AM solutions have been developed as compelling solutions for industries seeking precise and efficient micro manufacturing processes,” said Ziki Peled, president EMEA at Nano Dimension. “With the ability to create intricate structures and components on a micron scale, micro AM offers unparalleled design freedom and complexity, enabling the production of highly customized and optimized parts. This technology minimizes material waste and reduces the need for assembly by fabricating complex geometries in a single build, leading to improved overall efficiency. Industries such as electronics, medical devices, aerospace, and automotive are finding immense value in Micro-AM which is poised to play a pivotal role in driving innovation, cost-effectiveness, and competitiveness across various sectors in today’s rapidly evolving industrial landscape. Our suite of alternative micro AM solutions now allows us to meet the full range of strategic and application-specific customer requirements.”

The key difference between the Tera and Giga machines is essentially the build volume, with the smaller Giga machines being aimed at prototyping applications and the larger Tera machines aimed at higher volume production. Both the Tera 250 and the Tera 25 have a build volume of 50 x 50 x 100 mm, while the Giga 250 has a build volume of 6 x 9 x 45 mm and the Giga 25 a build volume of 12 x 18 x 45 mm.

Both the Tera and Giga machines are capable of micron-level resolution that is valued by OEMs, micro-manufacturers, and research and development centers. However, for companies looking to initiate prototype builds, the highly exacting resolution, tolerance attainment, and surface roughness capabilities of the Tera series are not necessary.

News Recommendation