New Process Enables 3D Printing of Small and Complex Components Made of Glass

Release Time:

2023-10-10

Because of its outstanding transparency as well as its stability in contact with heat or chemicals, glass is relevant for many high-tech applications.

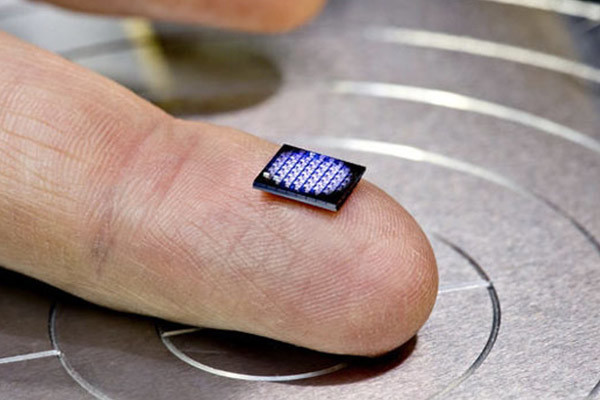

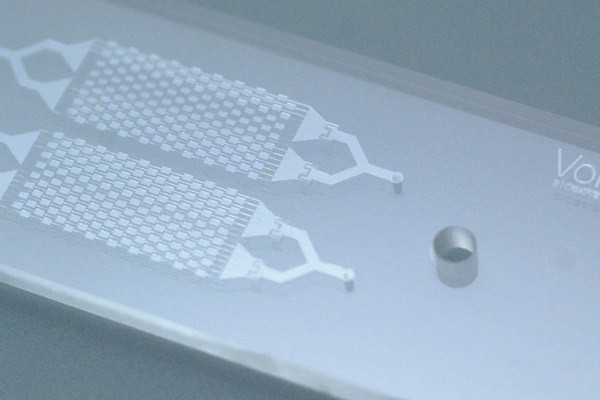

Because of its outstanding transparency as well as its stability in contact with heat or chemicals, glass is relevant for many high-tech applications. However, conventional processes for shaping glass are often tedious, energy-intensive, and quickly reach their limits for small and complicated components. The Freiburg materials scientists Dr. Frederik Kotz-Helmer and Professor Bastian E. Rapp, in cooperation with the University of California at Berkeley in the US, have developed a novel process that can be used to produce very small components from transparent glass quickly and precisely using micro 3D printing. Possible applications include components for sensors and microscopes, but also for lab-on-a-chip systems. The researchers were able to publish their results in the renowned journal Science.

The new technology is based on so-called Glassomer materials, which Kotz-Helmer and Rapp developed at the Department of Microsystems Engineering (IMTEK) at the University of Freiburg. “Glassomer materials consist of glass powder in a special plastic binder,” says Kotz-Helmer, “allowing to process glass like a plastic.” The resulting components are then placed in a furnace, which causes the plastic to burn and the glass to be sintered, i.e., densified. “In the end, the components consist of one hundred percent highly transparent fused silica glass,” says Kotz-Helmer.

News Recommendation

Address

No. 1 Rongchang Road, Huangbohai District, Yantai City, Shandong Province, China

Subscribe

Get the latest information from Moji Nano Technology

Scan WeChat QR Code to Contact Us