Tiny technologies for high-impact medical applications

Release Time:

2023-12-27

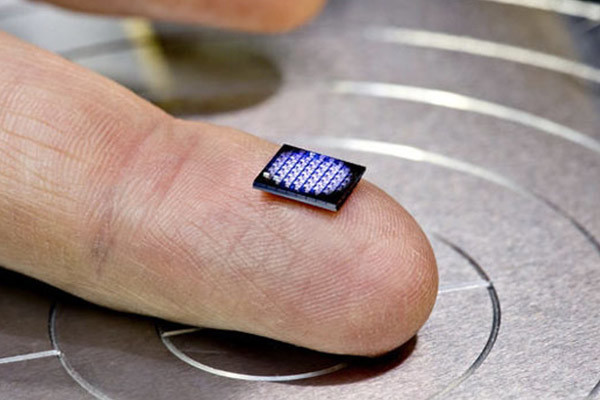

Nano 3D printing, with its incredibly high-accuracy parts measuring less than 100 nanometers, and micro 3D printing (a micron is a thousand times larger than a nanometer.

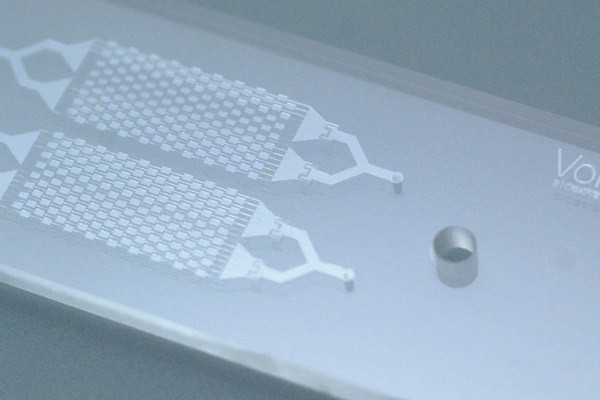

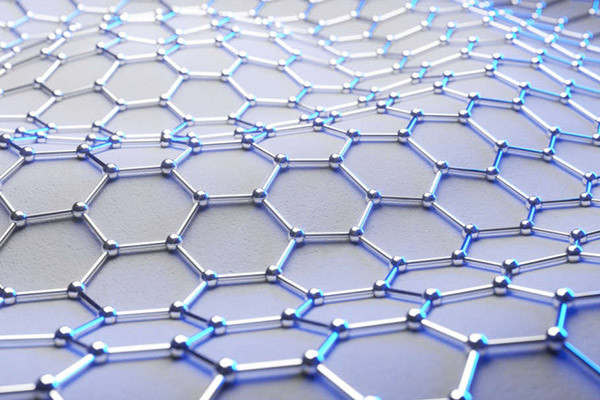

Nano 3D printing, with its incredibly high-accuracy parts measuring less than 100 nanometers, and micro 3D printing (a micron is a thousand times larger than a nanometer but is still just one thousandth of a millimeter) 3D printing have the potential to radically disrupt the medical device industry—more precisely, and less invasively. Devices for surgeries and laboratory equipment, which require high levels of detail, are often demanded in small batches. Over the past few years, many have leveraged this technology for just that. Let’s take a look at the companies and technologies that are leading this disruption, and what it means for the future of medical care.

Nano 3D printing technologies such as 2PP (Two-photon polymerization) and high-precision stereolithography have all seen great advancements through university research and via systems developed by academic teams, that often lead to a commercial spinoff company. As many will remember, one of the very first high-profile projects in nano 3D printing was a Formula 1 car produced via internally developed 2PP technology at the University of Vienna in 2012. The F1 car measured 285 microns in length, about the size of a grain of sand. Photographed with an electron microscope, the model was created using the latest version of two-photon lithography or 2PP, a 3D-printing technique in which highly focused laser beams manipulate liquid resin into detailed solid structures. Molecules in the resin, which induce polymerization to make it hard, are activated when they absorb two photons at once – that happens only at the center of the beam, hence the precision. It’s fast, too. The car, made up of 100 layers, was printed in just four minutes.

News Recommendation

Address

No. 1 Rongchang Road, Huangbohai District, Yantai City, Shandong Province, China

Subscribe

Get the latest information from Moji Nano Technology

Scan WeChat QR Code to Contact Us