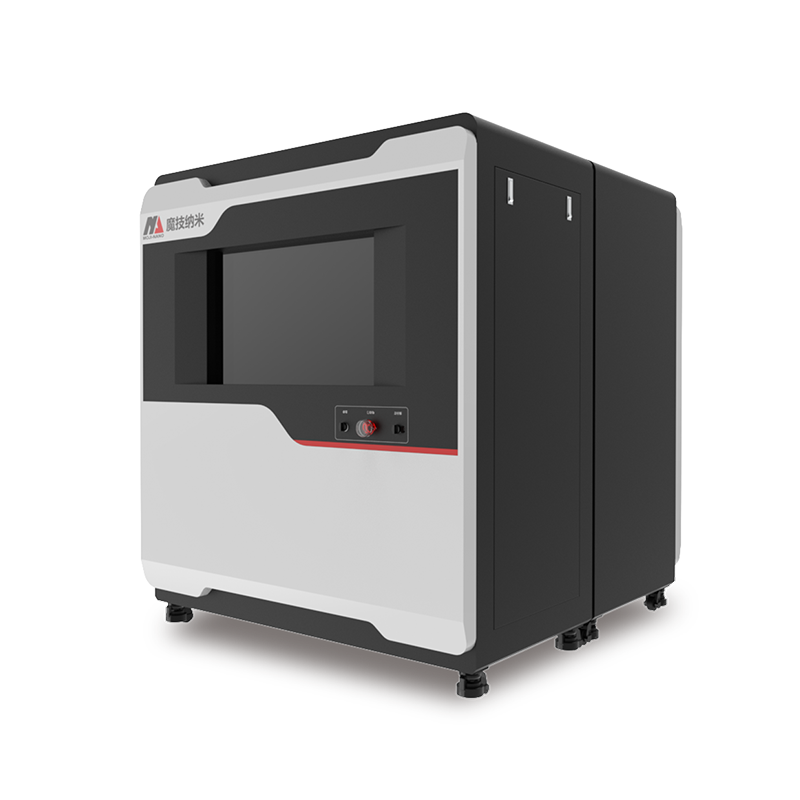

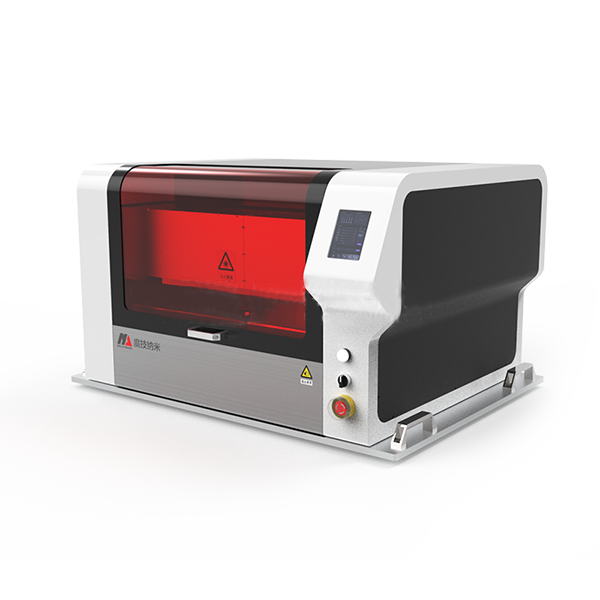

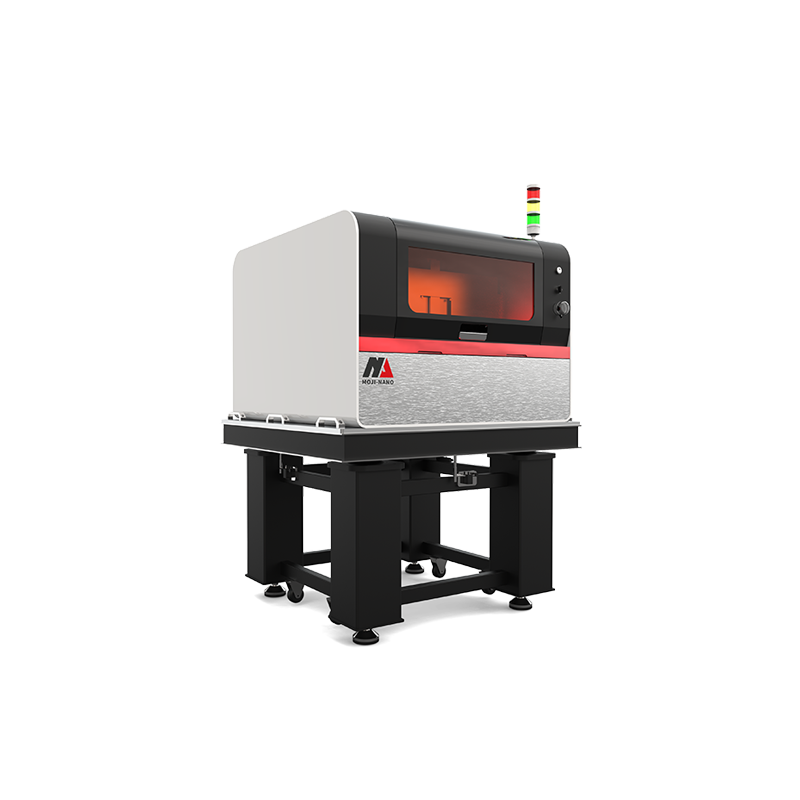

Application of three-dimensional lithography technology in microlens production

Release Time:

2024-10-30

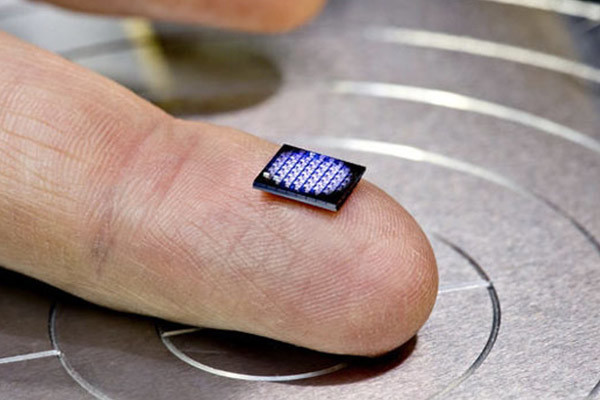

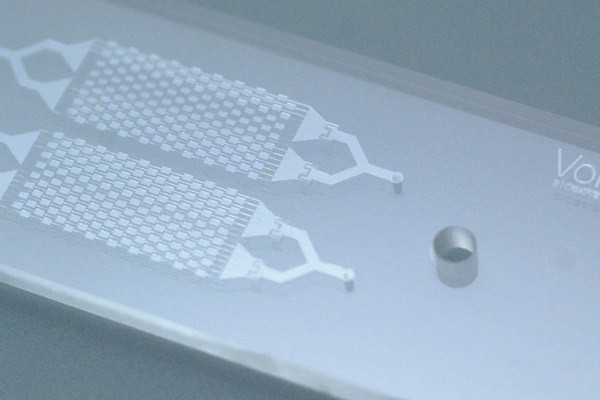

The microlens array is composed of sub-lenses with diameters from a few hundred nanometers to a few millimeters arranged in a certain order on the substrate, and the number of units ranges from a few thousand to tens of thousands.

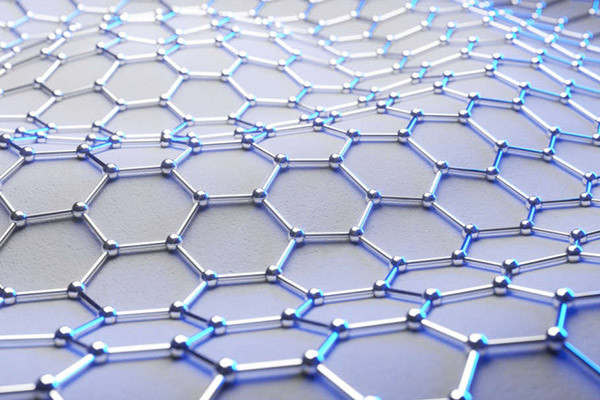

The microlens array is composed of sub-lenses with diameters from a few hundred nanometers to a few millimeters arranged in a certain order on the substrate, and the number of units ranges from a few thousand to tens of thousands.Since each sub-lens in the microlens array has a unique optical axis, if the parameters of all sub-lenses are the same, their optical properties should be the same, and when all the unit structures are used as an array as a whole, they have a main optical axis.Therefore, compared with the traditional single lens, the microlens array has extremely high parallelism. Each sub-lens can transmit optical signals independently of each other without interfering with each other, which is equivalent to the existence of a large number of two-dimensional parallel optical paths. Each sub-lens has the functions of transmitting optical information and transforming imaging.There are many ways to make microlens arrays. Let's list a few common production methods, and focus on the application of three-dimensional lithography technology in microlens production.

News Recommendation

Address

No. 1 Rongchang Road, Huangbohai District, Yantai City, Shandong Province, China

Subscribe

Get the latest information from Moji Nano Technology

Scan WeChat QR Code to Contact Us